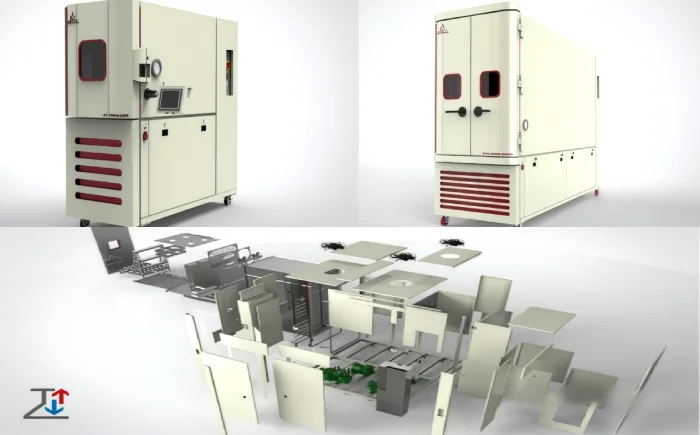

A temperature and humidity chamber is a specialized piece of equipment used to simulate varying temperature conditions for the purpose of testing and evaluating the performance, durability, and stability of products, materials, or components. Temperature Humidity Chambers are integral to many industries, including automotive, electronics, aerospace, and pharmaceuticals, where reliable operation in extreme temperatures is crucial. By allowing engineers and researchers to simulate extreme temperatures, ranging from deep cold to intense heat, Temperature and humidity test chambers help ensure that products meet quality standards, adhere to safety regulations, and perform consistently under expected (or even extreme) conditions.

What is a temperature and humidity chamber?

A temperature and humidity chamber is a controlled environment used to simulate specific temperature conditions. It allows the testing of products, materials, and components to evaluate their performance, reliability, and durability under varying temperature extremes.

Temperature and humidity test chambers are capable of controlling both temperature and humidity levels, making them invaluable for applications where products are exposed to fluctuating or extreme environmental conditions.

Temperature humidity chambers replicate the temperature challenges products may face in real-world environments, Temperature humidity chambers help ensure that products perform as expected and remain durable, reliable, and safe under various conditions.

Key Features of Temperature humidity chamber

Temperature and humidity test chambers are designed to recreate conditions that products might encounter during storage, transportation, and usage. Here are some essential features that make temperature humidity chambers versatile and highly effective:

- Wide Temperature Range

- Precise Temperature Control

- Rapid Heating and Cooling Rates

- Uniform Temperature Distribution

- Humidity Control

- Data Logging and Monitoring

- Programmable Profiles

- Touchscreen Interface

- Safety Features

- Insulated Construction

- Durable and Corrosion-Resistant Materials

- Flexible Interior Configurations

- Low Noise Operation

- Compliance with Testing Standards

- Energy Efficiency

Types of temperature and humidity chambers

There are several types of Temperature humidity chambers available, each designed for specific testing requirements. Choosing the right one depends on factors like the type of product being tested, required temperature and humidity ranges, and available space. Types of temperature and humidity test chambers incorporate:

Benchtop temperature and humidity chambers:

Click here for more information about Mini Chambers.

Compact chambers are designed for smaller samples or laboratory use. Temperature humidity chambers are ideal for limited testing needs, where space and sample size are not extensive.

The flexibility of the small temperature and humidity chamber allows for quick and targeted testing.

Researchers can efficiently assess the effects of temperature fluctuations on small samples, speeding up the testing process without compromising accuracy.

Best for: Small-scale testing, electronics, and research laboratories

Benchtop test chambers are compact and designed for limited space environments. Despite their smaller size, they offer precise control over temperature and humidity conditions. They are commonly used for testing small electronic components, medical devices, and materials in research settings.

Walk-in Chamber:

Walk-in Chamber or Large Temperature and humidity chamber accommodates more significant test samples or equipment, with the ability for personnel to walk inside for easy access. Walk-in test chambers provide ample space to test large products or multiple items at once.

Best for: Large product testing, aerospace, and automotive industries

Temperature and humidity chambers are ideal for industries requiring large-scale testing, such as automotive parts, aerospace components, and industrial equipment. Aryasarmayesh offers customizable walk-in chambers with advanced control systems for maximum accuracy.

Basic temperature and humidity test chamber:

Medium temperature test chamber

The Medium temperature humidity chamber play an important role in various industries by providing a controlled environment to simulate temperature conditions and evaluate their effects on materials, products, and electronic components.

These kinds of temperature chambers offer essential temperature and humidity control appropriate for common testing purposes.

Best for: Mid-sized products, electronics, pharmaceuticals

Reach-in chambers are medium-sized units that provide more capacity than benchtop models but are not as large as walk-in chambers. They are widely used in electronics, pharmaceutical, and packaging industries where precise environmental control is required for product stability testing.

Climatic test chamber:

A Climatic test chamber is a special room designed to simulate different climatic conditions to test and evaluate the performance of products under different environmental conditions.

Particularly planned for long-term steadiness testing, the Climatic test chambers give exact control over temperature and humidity for amplified periods.

Solar Radiation Test Chamber:

A UV chamber is a controlled environment designed to replicate the intensity and spectral distribution of natural sunlight. By reproducing the solar spectrum, these chambers allow manufacturers to test how products react to prolonged exposure to sunlight.

Thermal Shock Chambers:

Thermal Shock chamber quickly move test tests between extraordinary temperature conditions to assess their resistance to sudden temperature changes.

This type of testing helps to simulate real-world conditions where products may encounter sudden temperature fluctuations, allowing manufacturers to assess the durability, performance, and reliability of their materials or products when exposed to thermal stresses.

Best for: Durability testing, automotive, and defense industries

Thermal shock chambers subject products to sudden temperature changes to assess their durability under extreme conditions. This is essential for industries such as automotive, aerospace, and defense, where materials must withstand harsh environmental fluctuations.

Customized temperature and humidity test chamber:

Manufacturers may offer customized temperature and humidity chambers custom-made to particular testing prerequisites or businesses, giving specialized highlights or arrangements.

Best for: Unique industrial needs, research, and development

If your testing requirements do not fit standard chamber models, Aryasarmayesh offers custom-built temperature and humidity test chambers. These can be designed with specific temperature ranges, humidity controls, and special features such as vibration or UV exposure for advanced environmental testing.

How the Temperature Humidity Chamber Works

Ensuring that products can withstand different environmental conditions is crucial across industries like electronics, automotive, aerospace, and pharmaceuticals. Temperature and humidity chambers are designed to simulate real-world conditions, allowing manufacturers to assess product durability, reliability, and performance before market release.

Temperature humidity chambers are constructed with materials and components specifically designed to control and maintain extreme temperature ranges. They use refrigeration and heating elements to adjust the temperature inside the chamber, often in combination with humidity controls to create a wide range of testing environments.

A temperature and humidity chamber creates controlled environmental conditions by regulating temperature and moisture levels. The working mechanism involves multiple components, including sensors, control systems, cooling/heating units, and humidification systems.

1. Key Components of a Temperature and humidity chamber

To maintain precise environmental conditions, a test chamber consists of:

✔ Temperature Control System – Uses heaters and refrigeration units to create hot and cold conditions.

✔ Humidity Control System – Involves humidifiers and dehumidifiers to adjust moisture levels.

✔ Sensors & Controllers – Continuously monitor and adjust temperature and humidity.

✔ Air Circulation System – Ensures uniform conditions inside the chamber.

✔ User Interface & Control Panel – Allows operators to set, monitor, and adjust test parameters.

2. The Working Process of Temperature and Humidity Testing

Step 1: Setting the Test Parameters

Operators input desired temperature, humidity levels, and duration through a digital control panel. Aryasarmayesh chambers feature user-friendly interfaces for easy configuration.

Step 2: Temperature Regulation

The temperature and humidity chamber adjusts the temperature using a heating or refrigeration system:

- Heating: Electrical heaters raise the temperature when required.

- Cooling: A refrigeration system (compressor, evaporator, and condenser) reduces the temperature.

Advanced Temperature and humidity chambers by Aryasarmayesh offer fast temperature recovery times and precise control to meet industry standards.

Step 3: Humidity Regulation

The chamber’s humidification system increases or decreases moisture levels:

- Adding Humidity: Steam generators or ultrasonic humidifiers introduce moisture into the chamber.

- Removing Humidity: A dehumidification system (cooling coils or desiccants) extracts excess moisture.

Aryasarmayesh Temperature humidity chambers feature high-precision humidity sensors to maintain accurate conditions, ensuring reliable test results.

Step 4: Air Circulation & Uniformity

A built-in air circulation system distributes air evenly inside the chamber. This prevents temperature or humidity variations that could affect test accuracy.

Step 5: Real-Time Monitoring & Adjustments

High-accuracy sensors continuously track temperature and humidity. If deviations occur, the control system automatically adjusts heating, cooling, or humidification to maintain stable conditions.

Aryasarmayesh test chambers come with smart monitoring systems and remote-control capabilities, ensuring users can monitor and adjust tests effortlessly.

Step 6: Data Logging & Test Completion

Most modern chambers record test data for analysis. Aryasarmayesh chambers feature automated data logging and integration with quality control systems, making compliance with industry standards seamless.

Why Is Temperature and Humidity Testing Important?

Environmental factors like heat, cold, and moisture can significantly impact a product’s performance, durability, and lifespan. Without proper testing, manufacturers risk product failure, recalls, and financial losses. Here’s why this testing is essential:

1. Ensures Product Durability Under Extreme Conditions

Many products are exposed to fluctuating temperatures and humidity levels during transportation, storage, and use. Testing ensures they can withstand these conditions without degrading or malfunctioning.

✔ Example: Electronics, such as smartphones and circuit boards, undergo humidity testing to prevent condensation damage and short circuits.

2. Prevents Material Degradation

Humidity and temperature changes can cause materials to expand, contract, corrode, or weaken over time. Testing helps manufacturers select the best materials for long-term durability.

✔ Example: In the automotive industry, rubber seals, plastics, and metal parts are tested to prevent premature wear and corrosion.

3. Enhances Safety & Compliance with Industry Standards

Many industries have strict regulations requiring environmental testing to ensure safety, reliability, and compliance with global standards like ISO, ASTM, and IEC.

✔ Example: In the medical and pharmaceutical industries, drug packaging and medical devices must be tested to maintain their integrity under various conditions.

4. Reduces Product Failures & Warranty Claims

Unreliable products lead to customer complaints, costly recalls, and damaged brand reputation. By performing rigorous temperature and humidity tests, manufacturers can minimize defects and reduce warranty claims.

✔ Example: Automotive batteries undergo extreme temperature tests to ensure they function in both hot and freezing climates.

5. Improves Product Performance & Customer Satisfaction

A well-tested product performs consistently, leading to better user experience and customer trust. Companies that prioritize environmental testing often have a stronger market presence and competitive advantage.✔ Example: Aerospace components are tested under high-altitude, low-pressure, and extreme temperature conditions to ensure safety and performance during flights.

Applications Temperature Humidity Chambers

Temperature and humidity test chambers serve a broad range of industries, each with specific testing requirements:

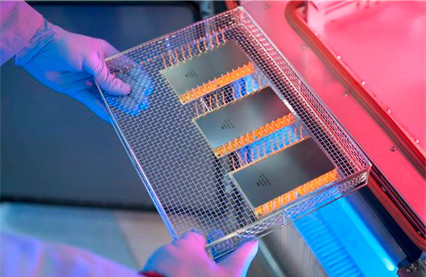

Electronics Testing

Electronics are particularly sensitive to changes in temperature and humidity. For example, high humidity can cause condensation on circuits, leading to corrosion, short circuits, or malfunctions. Temperature fluctuations can also cause materials to expand and contract, putting stress on components. Temperature and humidity chambers help manufacturers ensure that electronic products perform reliably under various environmental conditions.

Automotive and Aerospace Industries

Automotive and aerospace parts must endure extreme environments, such as intense heat, subzero temperatures, and high humidity. Components like engines, electronics, and even interiors are subjected to temperature and humidity testing to confirm they will function correctly in all climates and at all altitudes. For instance, interiors may be tested for how materials hold up in hot, humid conditions, while exterior parts may undergo tests to check resistance to frost, rain, or extreme heat.

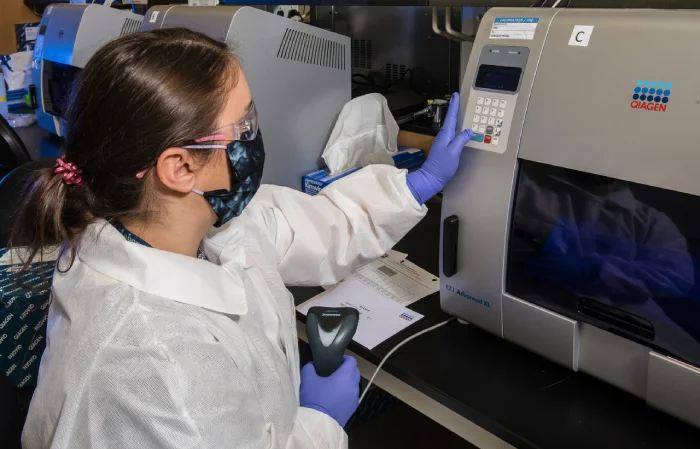

Pharmaceuticals and Biotechnology

Pharmaceutical products, biological samples, and medical devices often require storage under controlled conditions to ensure their efficacy and safety. Temperature and humidity test chambers allow these industries to simulate different storage environments, such as a hot, humid warehouse or a refrigerated space, verifying that products remain stable and effective throughout their shelf life.

Materials Testing

Materials like plastics, metals, and composites are tested in temperature and humidity chambers to assess how they react to prolonged exposure to certain conditions. For example, metal components are often tested for corrosion resistance, while plastics may be assessed for warping or cracking under temperature changes and humidity. This information is vital for determining the longevity and performance of materials used in products from packaging to construction materials.

Consumer Goods

Everyday products, from household appliances to clothing, must undergo environmental testing to ensure durability and performance. Temperature humidity chambers help test these goods to ensure they can withstand common environmental stresses. For example, an outdoor appliance may be tested in high heat and humidity to see if it remains functional or if adhesives hold up without failing.

The choice criteria for temperature and humidity chambers:

- Temperature range: Guarantee the temperature and humidity chambers can accomplish the required temperature extremes for your testing necessities.

- humidity Control: Search for chambers with exact humidity control capabilities to achieve the desired conditions precisely.

- size and Capacity: Consider the measure and capacity required to suit your test tests enough.

- Uniformity: Check for chambers with uniform temperature and humidity dispersion to guarantee reliable testing conditions.

- Control system: Assess the control framework for ease of utilization and precision in keeping up with set conditions.

- Durability and Reliability: Select a temperature and humidity chamber with vigorous development and dependable execution for long-term utilization.

- Safety Features: Seek chambers with security highlights such as overheating security and caution for out-of-range conditions.

- Budget: Consider the fetch of the chamber and how it fits inside your budget imperatives.

What is the Temperature and humidity chamber used for?

In the following, we will introduce the use of the temperature and humidity test chamber in detail:

- Product Testing

- Material Testing

- Environmental Simulation

- Quality Control

- Research and Development

- Accelerated Aging

- Shelf-life Studies

Why Choose Aryasarmayesh for Your Test Chamber Needs?

When selecting a temperature and humidity test chamber, quality, precision, and reliability are key. Aryasarmayesh stands out as a leading manufacturer of environmental test chambers with:

✔ Advanced Technology – Cutting-edge control systems for precise temperature and humidity regulation.

✔ Custom Solutions – Tailor-made chambers designed to fit unique testing requirements.

✔ Durability & Reliability – Built with high-quality materials for long-lasting performance.

✔ Industry Expertise – Years of experience providing test chambers for electronics, pharmaceuticals, automotive, and aerospace industries.

✔ Exceptional Support – Expert guidance from selection to installation and after-sales service

Conclusion

Selecting the right temperature and humidity test chamber is essential for accurate product testing. Whether you need a benchtop, walk-in, reach-in, or customized solution, Aryasarmayesh has the expertise to provide high-performance chambers tailored to your industry needs.

Related articles in Aryasarmayesh:

Review the types of climatic test chambers

The Role of Climatic Test Chambers in Environmental Simulation