The Medium Temperature Test Chambers, which are also known as the temperature chambers and temperature controlled chambers play an important role in various industries by providing a controlled environment to simulate temperature conditions and evaluate their effects on materials, products, and electronic components.

These temperature controlled chambers are sophisticated instruments designed to reproduce extreme temperatures from sub-zero to scorching temperatures, allowing manufacturers and researchers to evaluate product performance and reliability under a variety of climate scenarios.

Features of temperature test chamber:

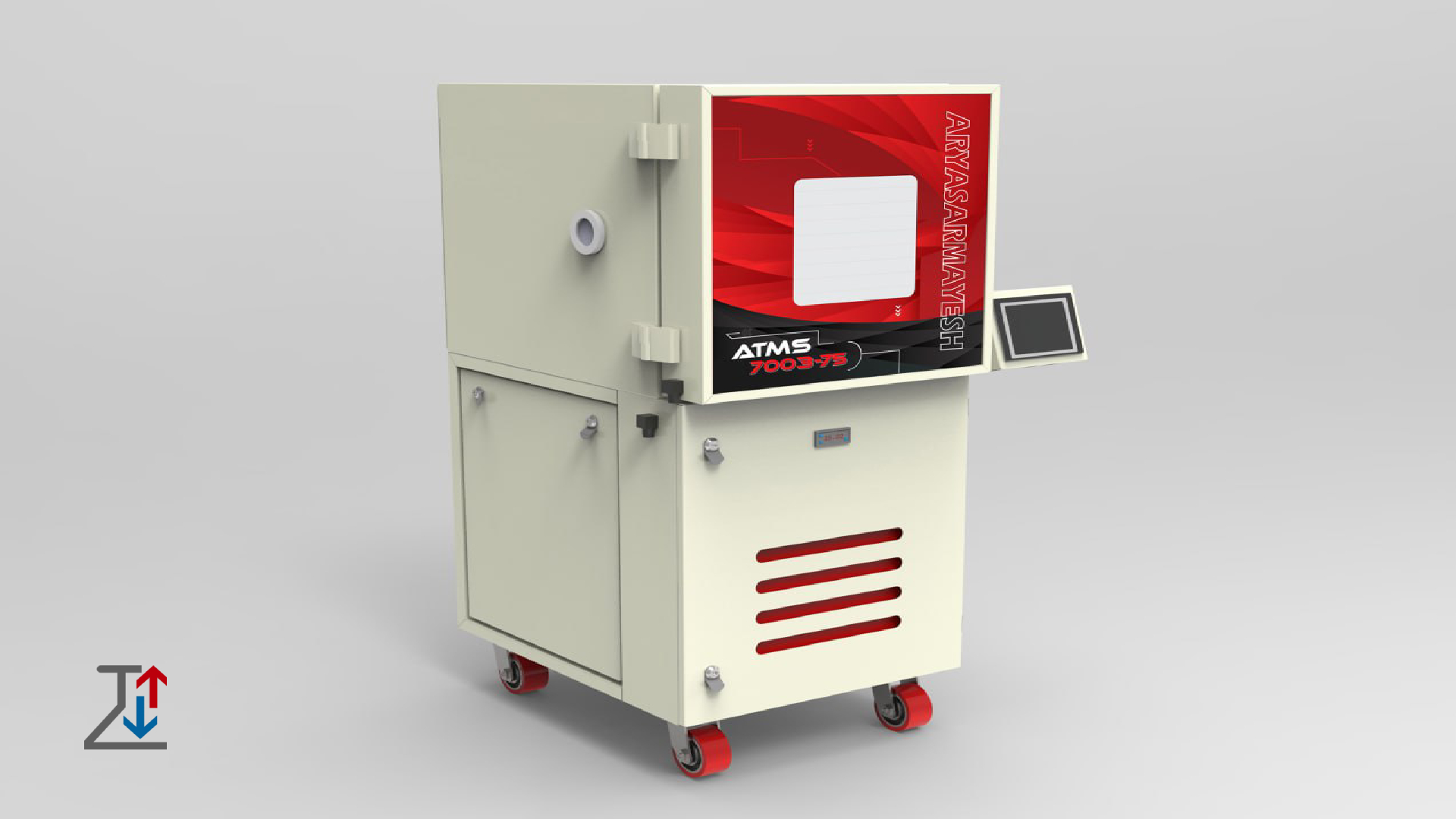

Aryasarmayesh temperature chambers offer unique advantages.

The features built into the temperature controlled chamber are divided into two general categories:

1- Standard features of the temperature controlled chamber:

This category of essentials is completely embedded in temperature test chambers.

2- Selected features of the temperature chamber:

To equip your device with these features, you need to order this product separately, so that it can be specially designed and made for you.

Standard features available in the temperature controlled chamber:

- 7inch full-color touchscreen

- Equipped with PLC

- Air condenser

- Water condenser

- 316 stainless steel plate exchangers in the middle evaporator in models with temperature systems that use a cooled water condenser

- The cooling system of the Temperature test chamber

- Security thermostat

- Physical security thermostat

- The door is equipped with 6 layers of glass

- Arya Soft software to run programs up to 100 segments and fix mode

- Equipped with SSR for the heater and long stainless steel fan shaft

- Equipped with an intelligent and optimized air distribution system

- Dry air injection system

- 100PT sensors calibrated in 10 points

- Possible error correction system of sensors in 6 zones in a non-linear way

- Equipped with rotating and locking wheels for easy carrying and Teflon height adjusters

- Stainless steel mirror test chamber and dampers regulating the acceleration of the air passing through the sensors

- Smart heater for the silicone strips around the door of the temperature test chamber

- French TECAMSE / German DWM / German BITZER compressors

- Equipped with DANFOSS / CARLY / C oil separator

Selected equipment of temperature controlled chamber:

- ADTL model dry air supply system, which is also a separate device

- Specific voltages

- Additional internal floors and additional port

- Communication software with computer and laptop by Modbus and Profibus network

- Custom dimensions and custom capabilities

- The possibility of installing compressors in a separate unit outside the test environment

- Software customization according to customer needs

- Installation of additional sensors with the ability to select them as reference sensors

- Adjustment of air acceleration by inverter

- Production of all kinds of chambers with rates desired by the customer

- Adding an open loop system (by liquid nitrogen and 2CO cylinders to access the temperature transfer rate at a higher speed in case of lack of space)

- Making special brackets to connect parts inside the test chamber

- Designing special nozzles and connections for gas injection

- Connection of ports required by the customer

How does the temperature test chamber work?

The working principle of a temperature test chamber can be explained by two physical parameters that the chamber can control: temperature and humidity control.

Temperature control

To control the temperature, the temperature test chamber must be able to perform both heating and cooling functions. It should also be able to evenly distribute the temperature inside the test chamber.

The mechanical cooling system of a temperature test chamber consists of a closed circuit system with the following main components:

- Compressor

- condenser

- Expansion valve

- Operator

Using the compression and expansion of refrigerant gas, this process evenly cools the temperature chamber.

The mechanical heating system consists of electric heating elements placed near the ventilation system, and the heated air is transported through the ventilation inside the test chamber.

Humidity control

To control the humidity, the test chamber must be able to perform dehumidification, it must also be able to distribute the humidity evenly in the test chamber.

Direct humidification is accomplished using an electric humidifier that injects steam through a hole in the airflow after the air circulation fan.

The temperature test chamber is dehumidified by a mechanical cooling system. Accordingly, when an object with a lower temperature is exposed to a higher ambient temperature, the moisture in the air condenses on the surface of the colder object. The evaporator is the element that has the lowest temperature inside the climate chamber and a dedicated part of it is used to reduce the humidity levels in the test chamber if necessary.

Temperature chamber design:

The temperature chambers are carefully designed and incorporate advanced technology to maintain precise temperature control.

One of the standout features of Aryasarmayesh’s temperature controlled chambers is their advanced temperature control technology.

For a free consultation with our experts, contact us.

The temperature controlled chambers offer a wide range of programmable temperature settings, allowing us to simulate various environmental conditions with meticulous accuracy.

The temperature chambers are equipped with highly sensitive sensors, heating and cooling systems, and advanced control interfaces. Temperature fluctuations within the chamber are programmable, allowing the simulation of specific climate profiles.

This level of control is indispensable in our industry, where products must endure diverse climates and temperature extremes.

For additional information about temperature chamber, refer to the table below.

What are The applications of a Temperature Test Chamber?

The main use of the temperature chambers is quality control during the manufacturing process.

Industries such as electronics, aerospace, and automotive rely on these chambers to subject products to rigorous temperature tests.

A temperature chamber ensures that items such as electronic equipment, aircraft parts, and auto parts can withstand the environmental conditions they may be exposed to during normal use.

By identifying vulnerabilities early in the development stage, manufacturers can make their products more durable and resilient.

Click here for more information about large Temperature Test Chambers.

The necessity of using temperature chambers in the industry:

Temperature controlled chambers have become an essential tool in a variety of industries, serving as the backbone of quality assurance and research and development efforts.

The ability to precisely control temperature conditions allows manufacturers and researchers to evaluate product performance and durability in a variety of environments.

As technology continues to advance, these temperature controlled chambers are likely to evolve and offer even more sophisticated features to meet the ever-increasing needs of modern industry.

Temperature test chamber price:

The complexity of striking a balance between design and function is reflected in the temperature test chamber price. Temperature controlled chambers are made to provide users with a reasonable amount of processing power and a size that can support a wide variety of uses. The temperature test chamber price considers elements including the level of detail in the environmental modeling, the capabilities of the user interface, and the technology integrated into the simulation.

Temperature test chamber price structure makes them available to a wide range of users, including academic institutions, research centers, and businesses looking for cost-effective yet useful environmental exploration solutions.

For Medium size temperature chamber price information, refer to the table below.

Purchase of Temperature Test Chambers:

The Purchase of this Temperature Chamber is more than a transaction; it’s a deliberate choice to partner with industry leaders who share our commitment to delivering top-tier solutions.

The Purchase of the Temperature Chamber is a transformative step forward in our pursuit of precision and reliability.

This strategic investment reaffirms our dedication to advancing quality assurance processes, integrating cutting-edge technology, and ensuring our products consistently meet the highest standards in a dynamic and demanding industry.

The purchasing process of the Temperature Test Chamber with Arayasarmayesh was smooth and provided a clear overview of product specifications, pricing, and customization options. Their commitment to providing value is clear and we appreciated their competitive pricing structure for the quality of equipment provided.

Purchase of temperature controlled chambers from Aryasarmayesh:

In today’s rapidly evolving business environment, ensuring product quality and reliability is paramount.

For manufacturing companies, investing in advanced test equipment has become a strategic imperative. One such important tool is a temperature chamber.

Temperature controlled chambers are equipment that simulates various environmental conditions to assess their impact on product performance. Aryasarmayesh is known for our commitment to innovation and precision engineering, offering a range of temperature chambers to meet the diverse requirements of modern industry.

For information on how to order the temperature controlled chambers, refer to the table below.

Temperature test chambers use advanced airflow systems to evenly distribute heated or cooled air throughout the interior, ensuring uniform temperature for consistent test results.

Yes, many models are designed with energy-saving features like high-quality insulation, energy-efficient components, and even power-saving modes to reduce operational costs.

Our team provides full support, including setup assistance, training, troubleshooting, and regular maintenance services. We’re here to help you get the most out of your test chamber.