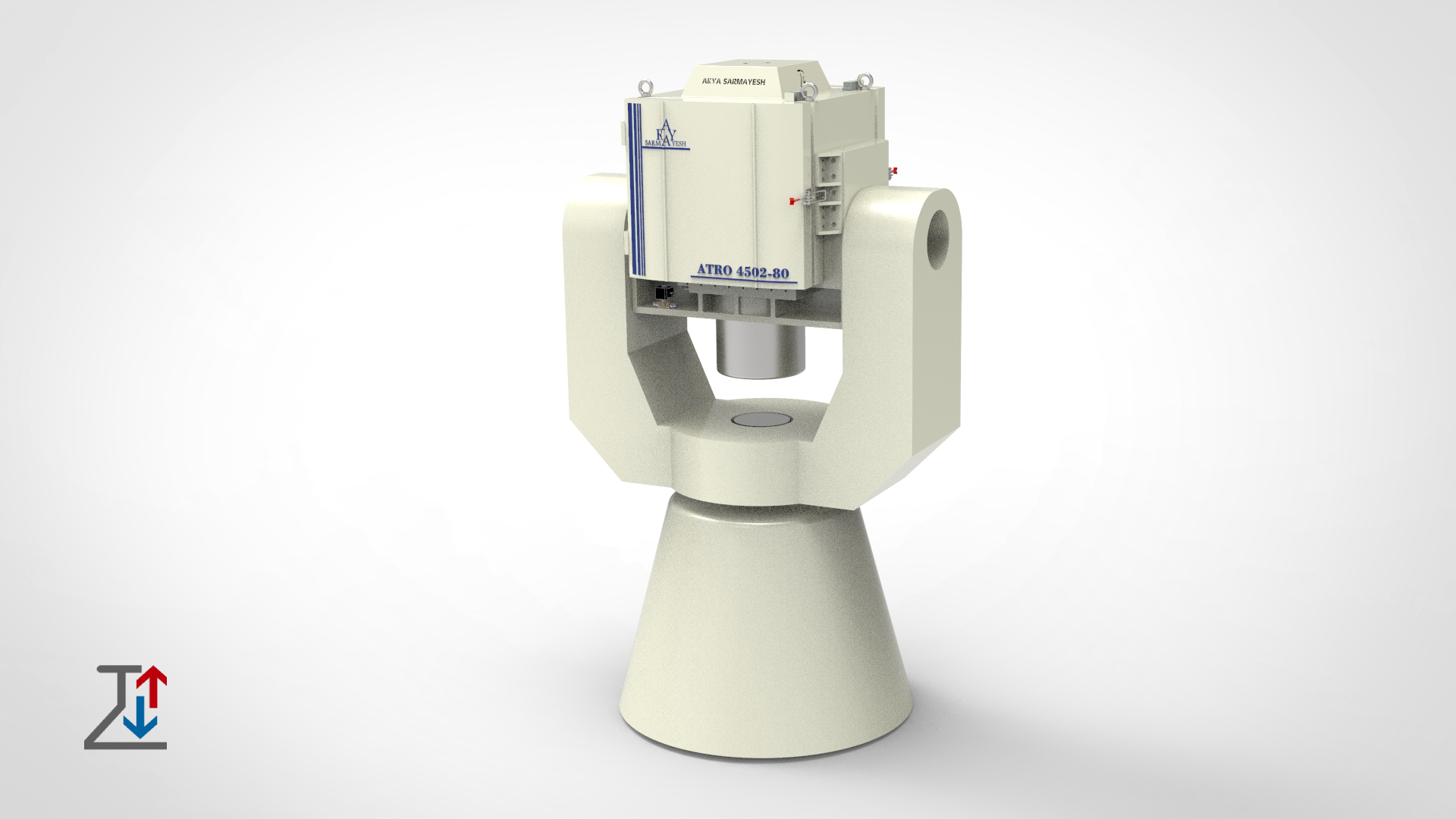

Environmental chamber is a ground-breaking invention in the field of precision testing and simulation because it provides three degrees of freedom to simulate real-world situations with unmatched accuracy.

Click here for more information about the Stair chamber.

In terms of dynamics testing, the tolerance environmental chamber is revolutionary because it provides unmatched accuracy and adaptability. environmental chamber enables researchers and engineers in the aerospace, automotive, electronics, and materials science industries to carry out accurate simulations, shorten testing schedules, and streamline product development procedures.

Features of the environmental chamber:

Environmental chambers offer unique advantages. The features built into the environmental chamber are divided into two general categories:

1- Standard features:

This category of essentials is fully installed in the environmental chambers.

2- Selected features:

To equip your device with these features, you need to order this product separately, so that it can be specially designed and made for you.

Standard features available in the environmental chamber:

- On a 7-inch full-color touch screen

- Equipped with PLC

- Use of 316 stainless steel plate exchanger in the middle evaporator Models with a temperature of -71 degrees Celsius and systems that use a water-cooled condenser

- Bypass system for cooling system

- Security thermostat (secondary protection system against high and low heat) internal and external

- Security physical thermostat (heater protection system in case of disconnection). Air circulation flow (external

- The door is equipped with 6-layer glass and internal lighting

- A floor number that can be regaled

- The location of removable floors

- Air Condenser / Water Condenser

- Aria Soft software to run the program up to 111 segments and fix mode

- The cable passage channel inside the 15 mm diameter chamber is equipped with permanent and temporary cover

- Equipped with SSR for heater and long fan shaft stainless steel Aria cooling and sealed umbilical

- Equipped with an intelligent and optimized air distribution system

- Equipped with dry air injection system into the chamber if available The presence of dry air to prevent the formation of dew

- Equipped with 100PT sensors calibrated in 11 points

- Equipped with a system for correcting possible errors of sensors in a non-linear way in 6 zones

- Equipped with rotating and locking wheels for easy carrying and a Teflon adjustment height maker

- Equipped with a stainless steel mirror test chamber and adjustable dampers Acceleration of the air passing over the sensors

- Equipped with a smart heater for the silicone strips around the door

- Equipped with French TECAMSE / German DWM / BITZER compressors German

- Equipped with oil separator DANFOSS / CARLY / C

Optional features and requirements of environmental chamber

- ADTL model dry air supply system can be provided as a separate device that is placed next to the environmental chamber and its connections will be connected to the chamber and has a separate software and is designed as an integral part of the environmental chamber itself and is designed by the software The chamber itself will be controlled.

- Specific voltages

- Additional internal floors and additional port

- Communication software with computer and laptop by Modbus network Probus

- Custom dimensions and custom capabilities

- The possibility of installing compressors in a separate unit and outside Of the test environment

- Software customization according to customer needs

- Installing additional sensors with the ability to select them as Reference sensor

- Adjustment of air acceleration by inverter

- Production of all kinds of environmental chambers with rates desired by the customer

- Adding an open loop system) with nitrogen cylinders

liquid and 2CO to access the rate of temperature transfer with a speed Higher in case of lack of space - Making special brackets to connect parts inside

Test chamber. - Designing special nozzles and connections for gas injection / Connecting the ports required by the customer

Comprehending the environmental chamber:

Acquiring the appropriate equipment is essential for promoting innovation and guaranteeing the dependability of materials and products in the field of advanced testing and simulation. The environmental chamber is a state-of-the-art option that provides unmatched flexibility in simulating actual settings.

Its environmental chamber is a state-of-the-art method for testing dynamics. This advanced device adds a new dimension by allowing rotational movement along three axes: pitch, roll, and yaw, in contrast to conventional chambers. Because of this three-dimensional freedom, complicated scenarios may be precisely simulated, giving a more accurate picture of how materials and products react to changing environments.

The tolerance environmental chamber capacity to subject materials to multi-axial stress situations is advantageous for materials science researchers. This makes it easier to comprehend material behavior as a whole and helps build stronger, more resilient materials for a range of applications.

Advantages of tolerance in an environmental chamber:

The tolerance environmental chamber allows for a realistic simulation of dynamic situations, giving a more accurate picture of how materials and products will perform in the settings in which they are intended.

The chamber’s capacity to replicate dynamic movements enables expedited testing, which yields important insights into material fatigue, possible failure causes, and overall durability in a shorter amount of time.

The information gathered by tolerance environmental chamber testing can be used by engineers to improve overall product performance, pinpoint weak points early in the development process, and optimize product designs.

Because the chamber can replicate real-world conditions, testing can be completed more quickly and efficiently because less time and money are needed for extensive testing campaigns.

Rotary Chamber price:

Businesses looking to improve their R&D capacities will find it crucial to comprehend the variables driving up the Rotary Chamber price.

The number of degrees of freedom and rotational movement precision are the main factors that determine the environmental chamber price. environmental chambers allow for more complex movements along several axes, increasing flexibility in testing settings. As a reflection of the sophistication of the chamber’s design, these movements’ superior precision frequently translates into a higher price.

Payload capacity, control system sophistication, and degrees of freedom are all important factors to take into account when comparing environmental chamber costs with three degrees of freedom. Finding a balance between these variables guarantees that your investment is in line with your spending plan as well as the particular testing needs of your apps. Give top priority to the chambers that provide the accuracy and adaptability you need to support your R&D projects.

Purchase of environmental chamber:

The purchase of an environmental chamber necessitates carefully weighing the possibilities for customization, testing needs, chamber specs, supplier reputation, and financial restrictions.

Investing in cutting-edge testing apparatus is essential to fostering innovation and preserving a competitive advantage as industries change over time. With careful selection and the acquisition of an environmental chamber featuring three degrees of freedom, you may enhance the level of accuracy in your testing pursuits.

purchase of the environmental chamber is a crucial step toward enabling enterprises and research institutes to raise the bar on innovation and establish themselves as leaders in their respective sectors. For people looking to fully utilize this cutting-edge equipment, it is essential to comprehend the subtleties of this technology and how it fits into particular application requirements.

This revolutionary instrument allows real-world dynamics to enter the controlled laboratory setting.

Invest in the purchase of the Rotary Chamber with 3 degrees of freedom to embrace the future of testing.