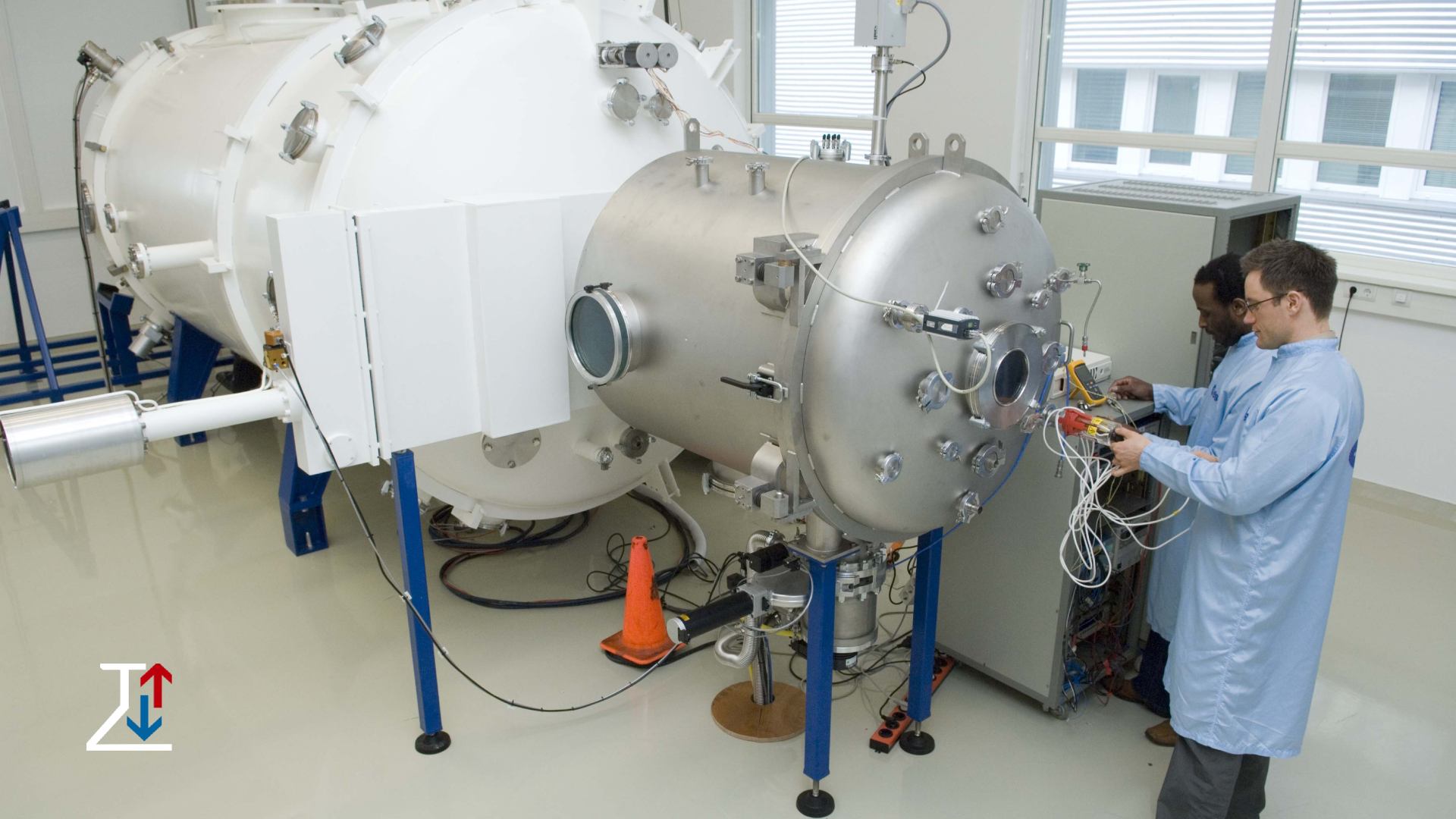

Thermal vacuum chambers are sophisticated testing environments essential to numerous fields, particularly in aerospace, defense, electronics, and materials science. These chambers simulate the extreme conditions of outer space, combining the capabilities of vacuum environments and thermal control. By replicating the harsh conditions of space, thermal vacuum chambers enable rigorous testing and validation of components and systems intended for extraterrestrial applications. So in this article, we will Explore Thermal Vacuum and answer this question What are thermal vacuum chambers used for?

Understanding Thermal Vacuum Chambers

A thermal vacuum chamber is an enclosed space where both vacuum and controlled thermal conditions are established. These chambers are designed to create low-pressure environments that mimic the vacuum of space, alongside a wide range of temperatures, which can be either very high or very low, to simulate the thermal conditions in space. The primary components of a thermal vacuum chamber include:

- Vacuum System: This system removes air and other gases from the chamber to create a near-perfect vacuum.

- Thermal System: This includes heaters and cryogenic cooling systems to control the temperature within the chamber.

- Instrumentation: Sensors and monitoring devices track environmental conditions and the performance of the test subject.

Key Applications of Thermal Vacuum Chambers

- Aerospace Testing:

- Satellite Components: Satellites and their components must endure the vacuum of space and extreme temperature fluctuations. Thermal vacuum chambers test these components to ensure they can survive and operate efficiently in space.

- Spacecraft Instruments: Instruments and scientific payloads on spacecraft are subjected to thermal vacuum testing to verify their functionality and reliability under space conditions.

- Thermal Control Systems: The effectiveness of thermal control systems designed to protect spacecraft from the harsh space environment is validated using thermal vacuum chambers.

- Defense and Military:

- Missile and Defense Systems: Military technologies, including missile systems, are tested in thermal vacuum chambers to ensure they can withstand the conditions encountered during high-altitude flight and space missions.

- Optical Systems: Advanced optical systems used in surveillance and targeting are tested for performance and durability in space-like conditions.

- Electronics and Semiconductor Industry:

- Space-grade Electronics: Electronic components intended for space missions, such as microprocessors and sensors, are tested in thermal vacuum chambers to ensure their resilience and functionality.

- Reliability Testing: High-reliability electronics, used in both military and commercial aerospace applications, undergo rigorous testing to identify potential points of failure.

- Materials Science:

- Material Properties: Researchers study how different materials behave in the vacuum and temperature extremes of space. This information is critical for developing new materials and improving existing ones.

- Outgassing Studies: Thermal vacuum chambers help assess the outgassing properties of materials, which is crucial for space missions to prevent contamination of sensitive instruments.

- Research and Development:

- Scientific Experiments: Researchers use thermal vacuum chambers to conduct experiments that require space-like conditions. This includes studying the behavior of fluids, biological samples, and chemical reactions in a vacuum.

- Development of New Technologies: New technologies and innovations are often tested in thermal vacuum chambers during the R&D phase to ensure they meet the necessary standards for space deployment.

Advancements in Thermal Vacuum Chamber Technology

Recent advancements have significantly enhanced the capabilities of thermal vacuum chambers, making them more efficient and versatile:

Enhanced Thermal Control:

Advanced heating and cooling systems allow for precise temperature regulation, enabling more accurate simulation of space conditions. This includes the ability to create rapid thermal cycling to test materials and components under stress.

Improved Vacuum Systems:

Modern vacuum pumps and control systems achieve higher levels of vacuum more quickly and maintain these conditions more efficiently. This reduces the time needed for testing and increases throughput.

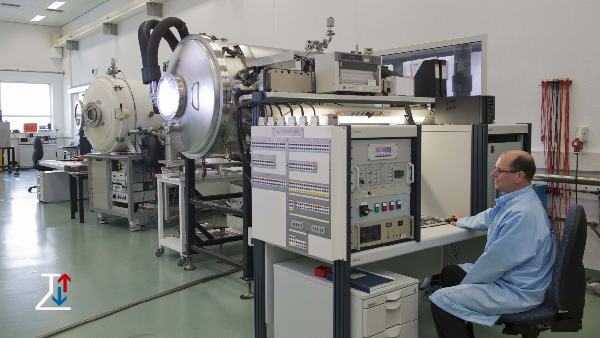

Automation and Data Acquisition:

Automation of testing processes and advanced data acquisition systems enable continuous monitoring and recording of test conditions. This ensures high-quality data collection and analysis, leading to better insights and more reliable test results.

Integration with Other Testing Methods:

Thermal vacuum chambers are increasingly being integrated with other testing methods, such as vibration testing, to provide a more comprehensive assessment of a component’s performance in space-like conditions.

Energy Efficiency:

New designs focus on reducing energy consumption and improving the environmental footprint of thermal vacuum chambers. This includes the use of more efficient insulation and cooling systems.

Challenges and Considerations

While thermal vacuum chambers are indispensable, they also present several challenges and considerations:

High Costs:

The construction, maintenance, and operation of thermal vacuum chambers are expensive. The initial investment and ongoing operational costs can be significant, particularly for large or highly specialized chambers.

Complexity of Testing:

Testing in thermal vacuum chambers requires careful planning and execution. The complexity of creating and maintaining the desired conditions can be technically demanding and time-consuming.

Safety Problems:

Operating a thermal vacuum chamber involves managing high voltages, extreme temperatures, and low-pressure environments, which pose safety risks. Proper safety protocols and trained personnel are essential.

Limitations in Size and Scale:

The size of the chamber limits the size of the components or systems that can be tested. For large spacecraft or components, this can be a significant limitation, necessitating alternative testing strategies.

Conclusion

Thermal vacuum chambers are crucial for the development and validation of technologies destined for space. Their ability to simulate the extreme conditions of outer space makes them invaluable for ensuring the reliability and performance of satellites, spacecraft, military systems, and high-reliability electronics. As technology advances, these chambers continue to evolve, offering even more precise and efficient testing capabilities. Despite the challenges and costs associated with their use, thermal vacuum chambers remain a cornerstone of modern aerospace and defense industries, driving innovation and ensuring the success of space missions.

Related articles in Aryasarmayesh: