In industries where materials are expected to withstand outdoor exposure, the UV weather test chamber plays a vital role in product testing and quality assurance. These specialized environmental testing devices simulate the damaging effects of sunlight, rain, and dew on materials to predict their long-term durability and performance.

What Is a UV Weather Test Chamber?

A UV weather test chamber, also known as a UV aging test chamber or UV accelerated weathering tester, is a laboratory device designed to replicate the environmental conditions that cause degradation in materials exposed to the outdoors. These chambers use ultraviolet (UV) light, humidity, and temperature cycling to simulate months or years of weathering in just a few days or weeks.

Accelerated ultraviolet exposure, commonly known as UV testing, can be carried out to understand how polymer materials withstand the damaging effects of UV light. This includes color change, reduction in performance characteristics, brittleness, and much more.

How the UV Weather Test Chamber Works

A UV weathering test chamber replicates outdoor aging conditions, especially sunlight, moisture, and temperature, under controlled and accelerated conditions. Here’s how the process works step by step:

UV Light Exposure: The chamber uses UV fluorescent lamps (UVA or UVB) to mimic the damaging wavelengths of natural sunlight. UV light breaks down chemical bonds in polymers, coatings, and other materials, simulating the photodegradation process that occurs outdoors. The intensity and wavelength can be controlled based on testing standards or specific material requirements.

Moisture Simulation (Condensation or Water Spray)

Moisture is introduced using either:

- Condensation: Heated water trays create humid air inside the chamber. Moisture condenses on the test samples, just like morning dew.

- Water spray (optional): Some chambers include spray nozzles to simulate rain or high-humidity bursts.

Temperature Control: The chamber uses built-in heaters to maintain a stable temperature, mimicking the heat exposure from the sun. This adds thermal stress, further accelerating material breakdown, especially in plastics and coatings.

Cycle Programming: Test cycles alternate between UV exposure and condensation phases (e.g., 8 hours UV, 4 hours condensation). This simulates day night and dry-wet cycles found in real environments.

Duration: A test can run for days or weeks to simulate months or years of outdoor exposure. Results can reveal how materials will fade, crack, peel, chalk, or weaken over time.

In summary, UV weather test chambers simulate the main components of weather exposure:

- UV Radiation: UV lamps, typically UVA or UVB fluorescent bulbs, mimic the sun’s radiation, which causes fading, cracking, and loss of mechanical properties in polymers, paints, and coatings.

- Humidity: Simulated dew and high humidity levels accelerate moisture-related degradation such as blistering, corrosion, and mold growth.

- Temperature Cycling: The chamber can cycle between high and low temperatures to simulate daily weather fluctuations.

Test cycles typically alternate between periods of UV exposure and condensation to simulate day-night and dry-wet conditions.

Key Features of UV Weather Test Chamber

UVA Lamps simulate short-wave UV radiation similar to sunlight at the Earth’s surface. Ideal for testing how materials resist photodegradation. UVB Lamps emit shorter wavelengths, accelerating degradation. Used when fast test results are more important than exact sunlight simulation.

The Programmable Heating System maintains a consistent and accurate test temperature, simulating solar heating effects. The Black Panel Thermometer measures the surface temperature of materials to monitor real-world thermal stress. The Condensation System mimics night-time dew formation by heating water trays and allowing moisture to condense on test surfaces. The Water Spray System simulates rain or sudden moisture exposure to evaluate water resistance or erosion.

Enables precise cycle programming of UV exposure duration, condensation phase, temperature setpoints, and lamp operation. Often includes data logging, error alarms, and USB or Ethernet ports for remote access or test record downloads. Adjustable racks hold flat or 3D samples in a vertical position for uniform exposure and allow testing of multiple materials or sample types simultaneously.

UV Weather Test Chamber applications

UV weather test chambers are widely used across industries, including:

- Automotive

- Construction

- Consumer Goods

- Electronics

- Textiles

Benefits of Using UV Test Chambers

A UV weather test chamber is a critical tool for simulating outdoor aging in a controlled environment. It works by exposing materials to UV light, heat, and moisture in cycles that mimic day/night and dry/wet conditions. Its key benefits include fast, reliable, and cost-effective predictions of product durability, helping manufacturers ensure quality, reduce risk, and comply with global testing standards.

- Accelerated Testing

- Predicts Long-Term Durability

- Ensures Product Quality

- Compliance with International Standards

- Cost-Effective Testing

- Versatility

- Suitable for a wide range of materials

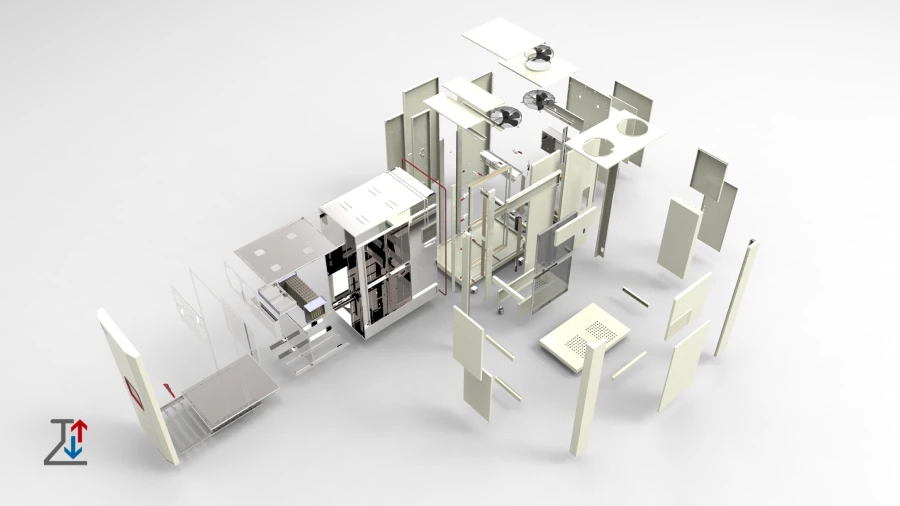

Aryasarmayesh’s UV Weather Test Chambers

In a world where product longevity and quality assurance are essential to maintaining competitiveness, Aryasarmayesh stands at the forefront of innovation with its UV Weather Test Chambers. Engineered with precision and built to meet international testing standards, Aryasarmayesh chambers deliver unmatched performance in accelerated weathering simulation, making them a preferred choice for research labs, manufacturers, and quality control departments.

Aryasarmayesh’s UV chambers are developed using advanced materials and state-of-the-art engineering, ensuring long operational life, minimal maintenance, and precise control over test conditions. Each unit is designed to simulate real-world degradation caused by sunlight, humidity, and temperature fluctuations, offering accelerated aging tests that reliably predict a product’s outdoor durability.

Ensure your materials and products meet the highest standards of durability and performance with Aryasarmayesh’s advanced UV weather test chambers. Designed for precision, consistency, and compliance with international testing protocols, our systems provide the confidence you need to validate long term environmental resistance.

To learn more about our solutions, request technical specifications, or receive a customized quotation, please contact our team of specialists.

Invest in proven technology, strengthen your quality assurance. Partner with Aryasarmayesh.

Conclusion

The UV weather test chamber is an indispensable tool for any industry where material durability under sunlight and moisture is a concern. Enabling accelerated aging tests ensures that products are built to last, meet regulatory requirements, and maintain their performance in real-world conditions.

Related articles in Aryasarmayesh:

Types of temperature test chambers

Test Chambers and Their Application in Simulating Climatic Conditions