A thermal vacuum chamber (TVC) is an essential tool in the aerospace and electronics industries, used to simulate the harsh conditions of space on Earth. These chambers allow engineers and scientists to test satellites, spacecraft components, and other equipment to ensure they can withstand the extreme temperatures and vacuum of outer space. By replicating the conditions of space, thermal test chambers provide critical insights into how materials and systems will perform once launched, reducing the risk of failure and increasing the reliability of space missions. This article delves into how does a Thermal Vacuum Chamber Work, highlighting its components, operation, and significance.

The Basics of a Thermal Vacuum Chamber

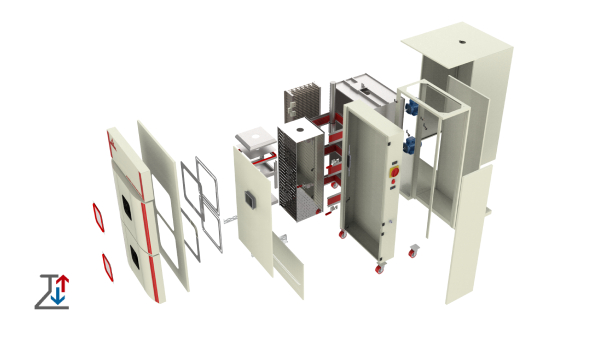

At its core, a thermal vacuum chamber is a sealed, insulated enclosure designed to recreate the vacuum and temperature extremes experienced in space. The chamber is typically cylindrical, with a door that allows the test object (often referred to as the “test article”) to be placed inside. Once sealed, the chamber can be evacuated to remove air, creating a near-perfect vacuum. Simultaneously, the chamber’s internal environment can be controlled to simulate the extreme cold and heat of space.

The vacuum aspect of the chamber simulates the low-pressure environment of space, where there is almost no atmosphere. The thermal aspect, on the other hand, replicates the vast temperature ranges experienced in space, from the intense heat of direct sunlight to the freezing cold of shadowed regions. These two features combined allow the TVC to provide a comprehensive simulation of space conditions.

Key Components of a Thermal Vacuum Chamber

A thermal vacuum chamber consists of several key components that work together to create the desired environment for testing:

Vacuum Pumps:

The vacuum pump system is crucial for creating a low-pressure environment inside the chamber. There are typically two types of pumps used in TVCs: roughing pumps and high-vacuum pumps. Roughing pumps first reduce the pressure to a lower level, and then high-vacuum pumps (like turbomolecular or cryogenic pumps) further reduce the pressure to simulate the vacuum of space. The goal is to achieve a vacuum level of about 10^-6 to 10^-8 torr, which is close to the vacuum found in low Earth orbit.

Thermal Control System:

This system is responsible for simulating the temperature extremes of space. It usually consists of thermal shrouds, heaters, and liquid nitrogen systems. The thermal shrouds, often made of highly reflective materials, can be heated or cooled to simulate the thermal radiation environment of space. Heaters within the chamber can raise the temperature, while liquid nitrogen, circulated through coils, is used to lower the temperature. This setup allows the chamber to mimic the thermal conditions a spacecraft would encounter in orbit, which can range from -180°C to over 150°C.

Chamber Walls and Insulation:

The chamber walls are designed to be airtight and thermally insulated. They are typically made from stainless steel to maintain structural integrity under vacuum conditions and to withstand the extreme temperatures. The insulation helps to minimize heat loss and maintain the desired temperature conditions inside the chamber.

Instrumentation and Monitoring Systems:

Accurate measurement and control are vital in thermal vacuum testing. Sensors within the chamber monitor temperature, pressure, and other environmental factors. Data acquisition systems collect this information in real-time, allowing engineers to adjust conditions and ensure that the test article is exposed to the exact parameters required. These systems are also critical for identifying any issues during the testing process.

Control Systems:

The control system is the brain of the TVC, integrating the various subsystems (vacuum, thermal, and instrumentation) to maintain the desired test conditions. Modern TVCs are equipped with computer-based control systems that allow for precise adjustments and automated test sequences. These systems can be programmed to simulate a wide range of space environments, ensuring comprehensive testing of the test article.

How a Thermal Vacuum Chamber Works

The operation of a thermal vacuum chamber typically follows a structured process:

Preparation:

The test article is carefully prepared and placed inside the chamber. All connections, such as power and data cables, are routed through feed-throughs in the chamber walls to maintain the vacuum seal.

Sealing and Evacuation:

Once the test article is secured, the chamber door is sealed, and the vacuum pumps are activated. The roughing pumps first lower the chamber pressure to a rough vacuum, and then the high-vacuum pumps take over to create a near-perfect vacuum. This process can take several hours, depending on the size of the chamber and the desired vacuum level.

Thermal Conditioning:

After achieving the required vacuum, the thermal control system is activated. Depending on the test requirements, the chamber can be heated or cooled to simulate the temperature extremes of space. For example, the thermal shrouds may be cooled with liquid nitrogen to simulate the cold of space, and then heaters may be activated to simulate the heat of the sun when the spacecraft is in direct sunlight.

Testing:

The test article is subjected to these conditions for a specified duration, often while undergoing operational testing. This phase is critical for evaluating the performance of the test article under space-like conditions. Engineers monitor the data in real time, looking for any signs of failure or degradation.

Return to Normal Conditions:

After testing, the thermal and vacuum conditions are gradually returned to normal. The chamber is slowly brought back to atmospheric pressure to avoid damaging the test article, and the temperature is stabilized. The chamber is then opened, and the test article is removed for further analysis.

The Importance of Thermal Vacuum Chambers

Thermal vacuum chambers are indispensable in space exploration. They help ensure that satellites, spacecraft, and other critical components can withstand the rigors of space. By simulating the vacuum and temperature extremes of space, TVCs allow engineers to identify potential issues before launch, reducing the risk of failure and improving mission success rates. Moreover, the data obtained from TVC testing is invaluable for improving the design and reliability of space-bound hardware.

In summary, a thermal vacuum chamber is a complex, highly controlled environment that plays a critical role in the development and testing of spacecraft and other technology intended for use in space. By understanding how these chambers work, we gain insight into the meticulous process required to prepare for successful space missions, ensuring that the technology we send into orbit can endure the challenges of the final frontier.