What is a Temperature Chamber and What Are Its Applications? A Comprehensive Guide to Temperature Testing

Ensuring the reliability and durability of products is crucial in high-stakes industries such as electronics, automotive industries, aerospace, and pharmaceuticals. One of the most effective tools for assessing performance under extreme conditions is the temperature test chamber, which allows products to be evaluated across a wide range of thermal environments.

This article explores the role of temperature chambers, their types, practical applications, and guidance for selecting the right unit for industrial testing.

Understanding Temperature Chambers

A temperature chamber is a controlled enclosure designed to replicate environmental conditions ranging from intense cold to extreme heat. These chambers allow engineers and researchers to:

- Observe how materials, components, and devices respond to temperature variations.

- Conduct long-term durability tests or rapid thermal shock experiments.

- Ensure compliance with international safety and quality standards.

By simulating realistic or extreme conditions, temperature chambers provide valuable insights into product performance before market release.

Types of Temperature Chambers

Temperature chambers come in different forms depending on the testing requirements:

- Standard Range Chambers: Suitable for general reliability testing, operating typically between -40°C and +150°C.

- Extended Range Chambers: Designed for advanced applications, such as aerospace or military, capable of -70°C to +180°C.

- Thermal Shock Chambers: Feature multiple zones with drastically different temperatures, allowing rapid transfer of samples to test resistance to sudden changes.

- Portable & Benchtop Chambers: Compact solutions for small-scale or laboratory testing.

Key Applications

Industries benefit from temperature chamber testing in several ways:

- Electronics: testing sensitive components like circuit boards and sensors.

- Automotive industries: Evaluating vehicle parts under extreme heat or cold.

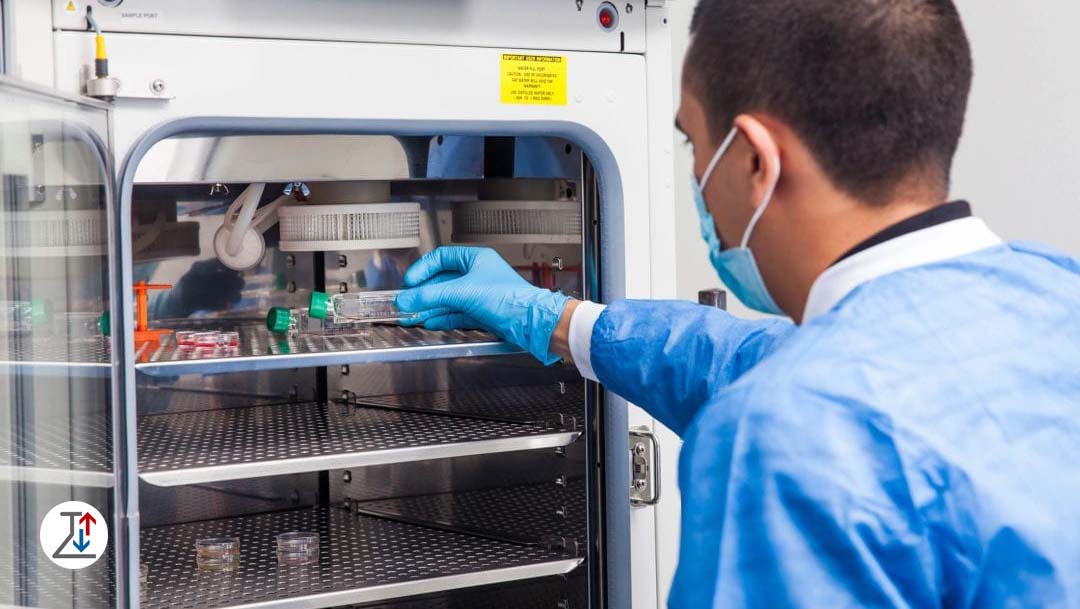

- Pharmaceuticals & Medical Devices: Ensuring medicine stability and reliable performance of medical equipment.

- Aerospace & Military: Simulating harsh environmental conditions to guarantee safety and performance.

- Material Science: Investigating changes in chemical or physical properties under thermal stress.

Choosing the Right Temperature Chamber

Selecting a chamber requires careful consideration of:

- Temperature Range – The minimum and maximum conditions your tests require.

- Chamber Size & Capacity – Must accommodate your samples comfortably.

- Rate of Temperature Change – Important for shock or rapid cycling tests.

- Control Accuracy – Essential for high-precision applications.

- Programmability & Data Logging – Useful for complex or repeated testing sequences.

- System Integration – Ability to connect with monitoring software or data analysis tools.

Benefits of Using Temperature Chambers

Integrating temperature chambers into testing workflows provides significant advantages:

- Quality Assurance: Verify product reliability before it reaches the market.

- Problem Detection: Identify potential weaknesses under extreme conditions.

- Extended Lifespan: Reduce failure rates and warranty claims.

- Regulatory Compliance: Meet international standards such as ISO, IEC, MIL-STD, and ASTM.

Maintenance and Support

Proper maintenance ensures accuracy and lastingness:

- Regular inspection of sensors and controllers.

- Scheduled calibration.

- Cleaning chambers and filters.

- Access to responsive after-sales service and spare parts.

Integrated Insights

Rather than separate FAQs, here are common considerations for engineers:

- Versatility: Chambers can test both very low and very high temperatures.

- Automation: Modern units allow multi-step programmable testing.

- Compliance: Equipment adheres to standards like ISO 16750, IEC 60068, and ASTM D4728.

Conclusion

A temperature chamber is more than a testing tool—it is a critical asset for industries where performance under thermal stress is essential. Selecting the appropriate chamber and maintaining it properly ensures product reliability, safety, and lastingness.

For sectors such as electronics, automotive industries, aerospace, and pharmaceuticals, investing in a temperature chamber is not optional—it is a necessity for quality assurance and competitive advantage.

We invite you to explore our other articles on the website.