Corrosion is a natural process where materials, especially metals, degrade over time due to chemical reactions with their environment. This degradation can severely affect product strength, appearance, and functionality. From automobiles to industrial machinery, corrosion can lead to premature failure, increased maintenance costs, and even dangerous safety hazards. For manufacturers, understanding and preventing corrosion is critical to ensuring product quality, longevity, and reliability.

Click here to view Aryasarmayesh’s Corrosion Test Chambers

What Is Product Corrosion?

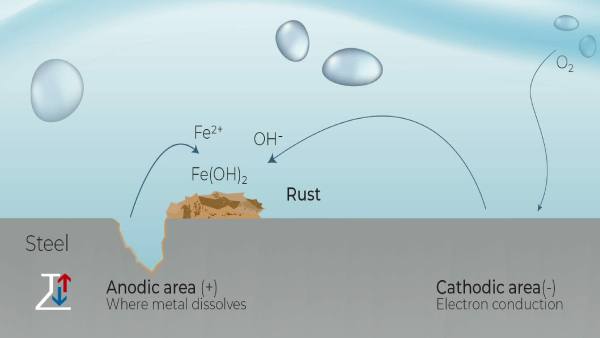

Corrosion is the result of chemical reactions, usually between a metal and its surrounding environment. Common forms of corrosion include rusting (the oxidation of iron in the presence of water and oxygen), pitting (localized attacks that cause small holes in metals), and galvanic corrosion (which occurs when two different metals are in contact in a corrosive environment). Each type of corrosion can have devastating effects on product performance.

While corrosion is most commonly associated with metals, it can also affect non-metal materials such as plastics, concrete, and wood. The rate and type of corrosion depend on several factors, including the material, exposure to elements like moisture or salt, and environmental conditions such as temperature and humidity.

Effects of Corrosion on Products

By implementing effective corrosion testing strategies, companies can safeguard their products against the damaging effects of corrosion and ensure long-lasting performance.

Structural Damage and Material Degradation:

One of the most obvious effects of corrosion is the weakening of materials. Rust and other forms of corrosion can reduce the structural integrity of metals, making them brittle or prone to cracking. This is a major concern in industries such as construction, automotive, and aerospace, where strong and durable materials are essential for safety.

Reduced Functionality:

In mechanical and electrical components, corrosion can lead to decreased functionality or even complete failure. For example, corroded electrical connections may result in power loss or short circuits. In engines and other machinery, corrosion can impede the movement of parts, leading to breakdowns and costly repairs.

Aesthetic Damage:

While some forms of corrosion, like patina on copper, are aesthetically pleasing, most forms cause unsightly stains, discoloration, or surface damage. This can lower the perceived value of products and harm a brand’s reputation, especially in consumer goods like home appliances and electronics.

Increased Maintenance and Replacement Costs:

Products that are susceptible to corrosion often require frequent maintenance to keep them in working condition. This includes cleaning, repainting, or replacing corroded parts. For manufacturers and consumers alike, these added costs can significantly impact profitability and satisfaction.

Safety Hazards:

In critical applications such as pipelines, bridges, or aircraft, corrosion can lead to catastrophic failures, posing serious safety risks. Corrosion in these cases may go unnoticed until a major incident occurs, making regular testing and prevention strategies essential.

Corrosion Testing:

Given the destructive potential of corrosion, manufacturers across various industries need to ensure that their products can withstand harsh environments. Corrosion testing is an essential part of the product development process, allowing companies to simulate real-world conditions and assess how their products will perform over time.

Corrosion testing can involve exposure to salt sprays, high humidity, temperature fluctuations, and other environmental factors that accelerate the corrosion process. By subjecting materials to these conditions in a controlled environment, manufacturers can predict their durability and identify weaknesses in their design or choice of materials. This testing is crucial for products used in harsh environments such as marine, automotive, and industrial applications, where corrosion is a constant threat.

Aryasarmayesh Manufacturer of Corrosion Test Chambers

Aryasarmayesh Company is at the forefront of providing advanced corrosion test chambers, designed to meet the needs of manufacturers across various industries. These chambers allow businesses to simulate and evaluate the effects of corrosive environments on their products, ensuring long-lasting performance and safety.

Key Features of Aryasarmayesh’s Corrosion Test Chambers:

With a focus on precision, durability, and international standards, Aryasarmayesh ensures that businesses across industries can protect their products and their reputation from the harmful effects of corrosion.

Advanced Environmental Control:

Aryasarmayesh’s corrosion test chambers are equipped with precise control systems to simulate a wide range of corrosive conditions. Manufacturers can test products under salt sprays, high humidity, and fluctuating temperatures, replicating the harsh conditions products may face in the real world.

Compliance with International Standards:

Aryasarmayesh’s test chambers are designed to meet international standards. This ensures that products tested in their chambers meet global quality and safety requirements, making them ready for international markets.

Customizable Testing Solutions:

The corrosion test chambers from Aryasarmayesh can be customized to suit different industries and testing needs. Whether testing automotive components, electronics, or industrial machinery, manufacturers can adjust the chamber settings to mimic specific environmental conditions relevant to their products.

High Durability and Precision:

Aryasarmayesh’s chambers are built with high-quality materials that resist wear and tear, ensuring long-term reliable use. Their precision engineering allows for accurate simulation of corrosive environments, giving manufacturers confidence in the results of their tests.

User-Friendly Interface:

Equipped with intuitive control panels and software, Aryasarmayesh’s corrosion test chambers make it easy for operators to set testing parameters, monitor progress, and record data. This ease of use ensures that companies can integrate corrosion testing into their product development processes efficiently.

Broad Range of Applications:

Aryasarmayesh’s chambers are used in a wide variety of industries, including automotive, aerospace, construction, electronics, and more. Any business that deals with metal components, coatings, or materials exposed to environmental wear can benefit from their advanced testing solutions.

Conclusion

Corrosion remains one of the biggest challenges for manufacturers, as it can lead to product failure, increased costs, and safety risks.

Aryasarmayesh Company provides world-class corrosion test chambers that enable manufacturers to test their products in controlled environments rigorously. Investing in corrosion testing is not just about product longevity it’s about ensuring reliability, safety, and success in the marketplace.