Structure and Materials of Test Chamber Interiors

In environmental testing equipment, the compartment that the interior space plays a vital role in both the precision of experiments and the lastingness of the device. The materials chosen for this space, along with a thoughtfully engineered design, can significantly influence the reliability of results and the overall lifespan of the chamber. Poor material selection or flawed design may compromise the device’s performance and reduce the trustworthiness of the collected data.

What Is a Test Chamber Interior?

The interior space, often referred to as the test space, is where the sample is placed to undergo controlled conditions such as temperature fluctuations, humidity cycles, thermal shocks, or pressure variations.

Given that this area is exposed to extreme environmental changes, it is critical to use materials that:

- Resist corrosion over time

- Conduct heat evenly

- Remain chemically stable and non-reactive

- not being polluted and easy maintenance

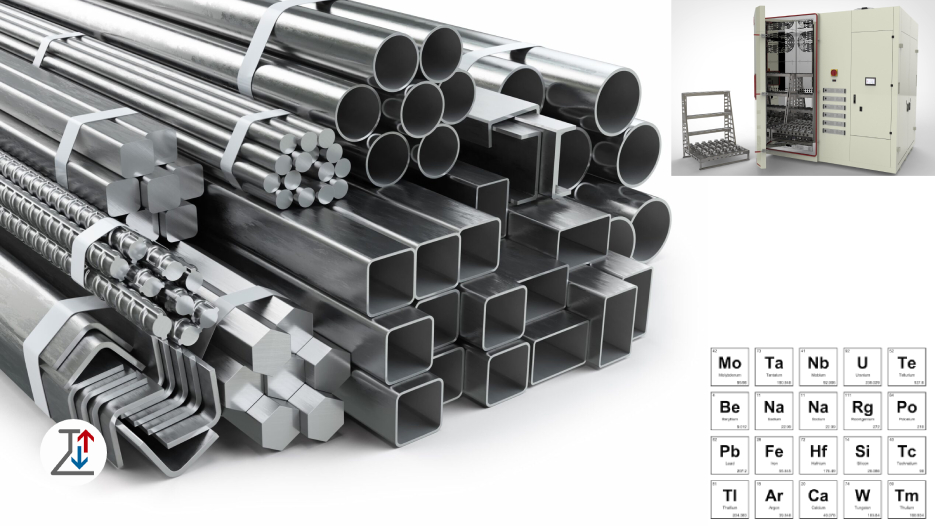

Common Materials for Chamber Interiors

Stainless Steel (304 or 316)

- The most widely adopted material for modern test chambers

- Advantages:

o Superior resistance to corrosion and rust

o Easy to clean and sanitize

o Tolerates high temperatures (300 °C or more)

o Smooth, non-reactive surface

- 304 vs 316:

o Grade 316 contains additional alloying elements that make it more resilient to harsh chemicals, making it ideal for salt or acid exposure tests.

Aluminum Alloys

- Less common, generally used in portable or budget-friendly chambers

- Pros:

o Lightweight construction

o Excellent thermal conductivity

- Cons:

o Lower corrosion resistance than stainless steel

o Often requires protective coatings such as anodizing

Galvanized or Painted Steel

- Rarely employed in contemporary designs, mainly in cost-sensitive or low-risk applications

- Drawback: Vulnerable to moisture-induced rust over time

Key Features of an Optimal Interior

- Chemical resilience: Can withstand vapors, salts, and testing chemicals

- Uniform heat distribution: Ensures consistent temperatures across the chamber

- Ease of cleaning: Essential in medical and pharmaceutical testing

- Mechanical strength: Able to handle pressure, thermal shocks, and samples weight

- Non-porous surfaces: Prevents moisture retention and contamination

Why Material Selection Matters

- Accuracy of tests: Inappropriate materials may distort results

- Chamber lastingness: Internal corrosion is a common cause of failure

- Safety: Some materials can react with samples, creating hazards

- Maintenance efficiency: High-quality materials simplify cleaning and upkeep

Design Considerations for Interiors

- Precision welding without gaps or seams

- Rounded corners to prevent moisture accumulation

- Venting provisions for vapor release if needed

- Anti-stick coatings (e.g., Teflon) for specialized applications

Conclusion

The interior of a test chamber is truly its “heart,” directly impacting the performance, reliability, and safety of experiments. Choosing premium materials like high-grade stainless steel not only enhances durability but also ensures dependable and accurate testing outcomes.

At Arya Sarmayesh, we construct our chamber interiors using top quality stainless steel to deliver long lasting performance and reliable operation for our customers’ testing needs.

Also, see the following article: