A compressor is the essential component of any refrigeration setup. Without it, neither cooling nor heating cycles can operate effectively. In industrial refrigerators, cold storage rooms, and environmental test chambers, the compressor’s proper function is crucial for maintaining steady temperatures and controlled conditions. This article delves into the compressor’s operation, its main elements, and how its performance differs in testing versus industrial applications.

The Working Principle of Compressor

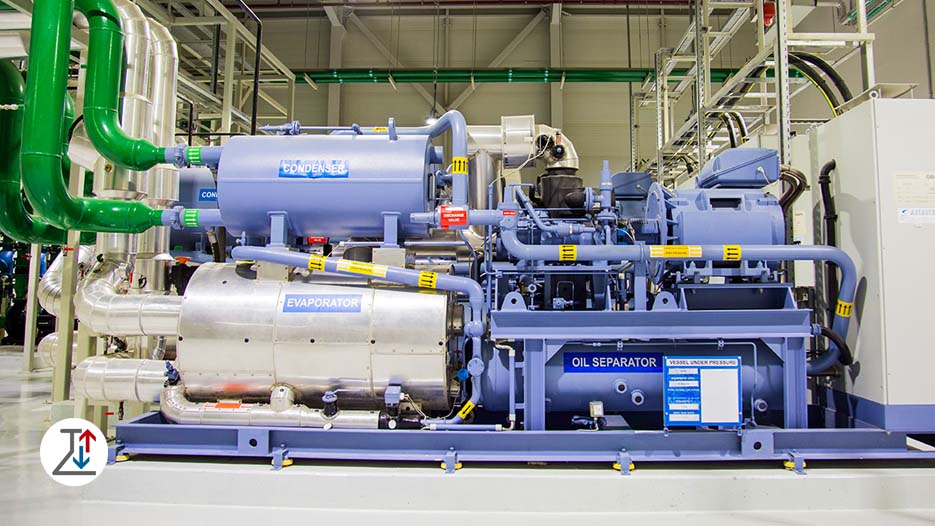

Cooling systems rely on a closed-loop process called the vapor-compression cycle. In this cycle, a refrigerant circulates continuously through four primary components:

- Compressor

- Condenser

- Expansion valve

- Evaporator

The compressor’s role is to kickstart the cycle by drawing in low-pressure refrigerant vapor from the evaporator and compressing it, which raises both temperature and pressure. This high-pressure gas then passes through the condenser, where it releases heat and converts into a liquid state. The continuous repetition of this process keeps the internal environment cool.

Key Stages in Compressor Operation

- Suction Stage:

Low-pressure and cold refrigerant enters the compressor from the evaporator.

- Compression Stage: The piston or screw mechanism compresses the refrigerant to raise its pressure and temperature.

- Discharge Stage: The high-pressure and hot refrigerant leaves the compressor and moves to the condenser to release heat.

This cycle repeats continuously to ensure the system maintains the target temperature.

Different Types of Compressors for Industrial and Test Applications

Depending on size of the system and intended use, various types of compressors are employed:

1. Reciprocating Compressors: Work like a piston engine and are suitable for smaller refrigerators or test chambers. They are relatively easy to maintain.

- Scroll Compressors: Offer high efficiency, quiet operation, and precise temperature control. They are often used in temperature and humidity test chambers for sensitive applications.

- Screw Compressors: Ideal for large-scale industrial systems or cold storage rooms with high thermal loads. They are capable of continuous operation at high pressures.

- Centrifugal Compressors: Used in larger ventilation systems or laboratory test chambers where precise energy management is needed.

Compressors in Environmental Test Chambers

In test chambers, the goal extends beyond mere cooling; maintaining precise temperature and humidity is essential. Compressors in these settings must adjust rapidly and accurately across a wide range of temperatures.

Two-stage or multi-circuit compressors are often employed to achieve finer control and improved energy efficiency. Modern units also incorporate inverter drives for electronic control, allowing compressor speed to adjust according to real-time cooling demands.

Maintenance Tips to Maximize Compressor Life

To maintain performance and extend the lifespan of compressors, the following practices are crucial:

- Regularly checking oil level and quality

- Monitor suction and discharge pressures

- Keep condensers and filters clean

- Prevent moisture or foreign particles from entering the refrigerant loop

- Ensure proper functioning of sensors and expansion valves

High pressures and rapid temperature swings in test chambers can accelerate wear, making scheduled maintenance essential.

Conclusion

The compressor is more than just a refrigerant pump; it is the heart of the cooling cycle. In environmental test chambers, its precision ensures reliable test outcomes. In industrial refrigeration and cold storage, its efficiency and durability directly affect energy consumption and maintenance costs.

Selecting the right type of compressor, designing an effective control system, and adhering to proper maintenance routines are critical to achieving stable, dependable cooling performance.