Buying Test Chambers: Key Insights for Choosing the Right One

Test chambers play a crucial role in laboratories, manufacturing facilities, and R&D centers, allowing products to undergo simulated environmental conditions to evaluate their performance and durability. Whether you deal with electronics, pharmaceuticals, automotive parts, or industrial goods, selecting the appropriate chamber ensures product quality, safety, and long- lasting. In this guide, we explore practical and technical tips to help you choose the most suitable test chamber.

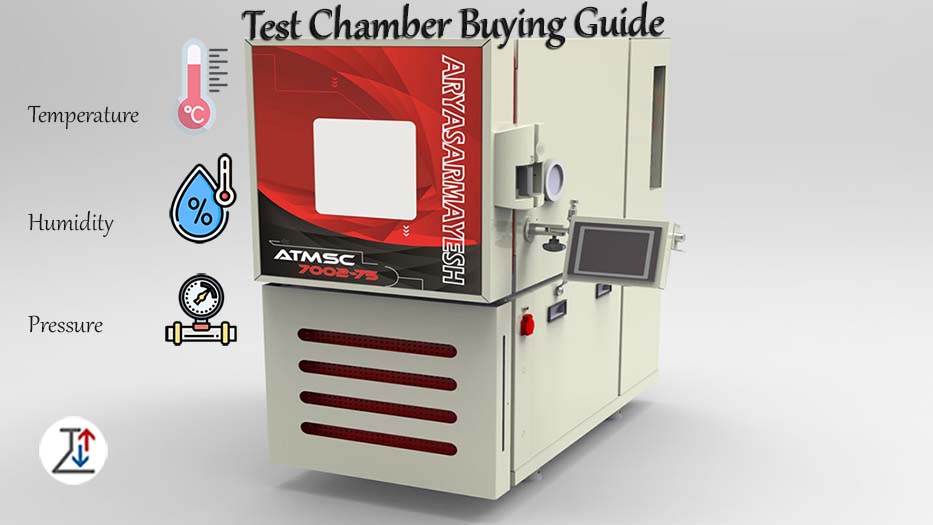

Types of Test Chambers and Their Uses

Temperature Chambers

Purpose: Examine how products respond to varying temperatures, replicating both hot and cold environments.

Typical applications: Electronic components, batteries, mechanical parts, food products.

Purchase considerations:

Temperature accuracy and uniformity: Ensure the chamber distributes heat consistently with minimal variation.

Rate of temperature change: Check how quickly the chamber can adjust temperature, which is vital for stress testing and simulating real-world conditions.

Internal capacity: Products should fit comfortably, with enough space for air circulation.

Humidity Chambers

Purpose: Test product resilience under different moisture levels.

Typical applications: Electronics, pharmaceuticals, food products, clothing.

Purchase considerations:

Adjustable humidity range with precise control.

Even distribution of moisture.

Option to combine with temperature testing (Temperature & Humidity Chambers) for realistic simulations.

Pressure Chambers

Purpose: Evaluate products under varying pressure levels.

Typical applications: Hydraulic and pneumatic equipment, automotive components.

Purchase considerations:

Ability to maintain stable pressure.

Safety systems to protect operators.

Compliance with international standards.

Dust Chambers

Purpose: Simulate dusty environments to assess product durability.

Typical applications: Vehicles, industrial equipment, power tools.

Purchase considerations:

Meet dust protection standards (e.g., IEC 60529 IP5X/IP6X).

Easy cleaning and maintenance.

UV / Sunlight Chambers

Purpose: Replicate sunlight or UV exposure to test material and coating resistance.

Typical applications: Plastics, paints, outdoor products.

Purchase considerations:

Adjustable intensity and wavelength.

Even light distribution.

Ability to simulate day-night cycles for long-term testing.

Essential Tips for Buying a Test Chamber

1.Define your testing needs

Before purchasing, clarify the environmental conditions your product must withstand: temperature, humidity, pressure, dust, UV, or combinations of these.

2.Precision, uniformity, and change rate

High precision ensures reliable, repeatable results.

Uniform distribution of temperature and humidity prevents hotspots or dry zones.

Fast response to environmental changes is critical for stress tests and realistic simulations.

3.Internal capacity and size

Choose a chamber that comfortably accommodates your products while allowing sufficient airflow for consistent testing conditions.

4.Standards and certifications

Verify that the chamber meets international standards such as ISO, ASTM, or IEC to guarantee trustworthy results.

5.Warranty and after-sales support

A strong warranty and comprehensive support—including maintenance, technical assistance, spare parts availability, and operator training—ensure long-term reliability. Aria Sarmayesh, a knowledge-based company, offers chambers with verified warranties and robust after-sales services, giving clients peace of mind.

6.Customization options

Our chambers can be tailored to meet specific client requirements, including size, capacity, temperature and humidity ranges, and other specialized features. This flexibility ensures your products are tested under the most relevant conditions.

7.Safety and alert systems

Chambers for pressure, temperature, and UV testing must include safety mechanisms and alarms to prevent accidents. Automatic shutdowns or operator alerts mitigate serious risks.

8.Maintenance and energy efficiency

Consider energy consumption, routine maintenance needs, and spare part costs to make an informed economic decision.

Conclusion

Choosing the right test chamber is more than just acquiring laboratory equipment. Accuracy, uniformity, temperature change rates, standards, capacity, warranty, and support are all critical factors that guarantee product performance and longevity.

Arya Sarmayesh offers high-quality chambers with various rate capabilities, full warranties, professional after-sales services, and custom solutions to ensure your products are tested in the most suitable environmental conditions. By following these practical guidelines, you can confidently select a reliable test chamber tailored to your needs, achieving precise and trustworthy environmental testing results.

Please also visit our Products page.